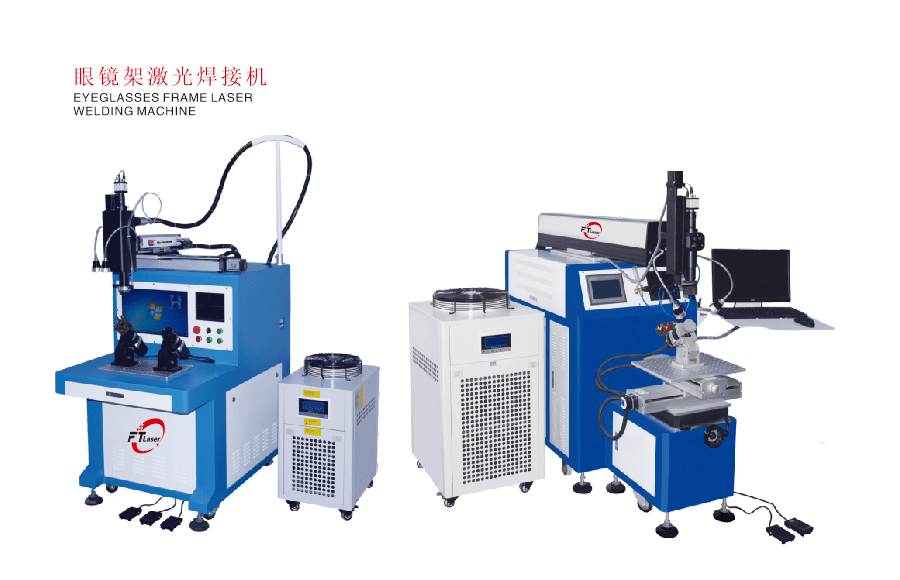

PRODUCT DESCRIPTION

This equipment is mainly developed for lens frames, dental nails, pipes and glasses. Its principle is to produce high temperature through continuous pulse laser focusing, fuse stainless steel materials or titanium metals, and cooperate with professional computer software automatic control system to achieve one-time welding of the whole body to the end. This equipment is improved on the first generation of eyeglass welding machine. It uses a touch power supply with LCD display, which can intelligently control the working current, repetitive working frequency, pulse width and spot diameter of the lamp. Compared with the first generation of machine, it has faster speed, smoother welding spot and higher quality.

APPLICATION

Various types of stainless steel and titanium alloy eyeglass frames, dental nails, pipes and eyeglasses.

Advantages of spectacle frame laser processing compared with traditional high-frequency welding

01. The processing speed is faster than that of high-frequency welding machine. The thermal deformation and heat affected zone are small, and the mirror frame will not become soft after welding.

02. The light spot of the weld is smooth, the surface is flat, and the welding penetration is very strong. Compared with the high-frequency welding machine, it is more difficult to drop the weld

03. It can process parts with complex properties and small parts. It can be synthesized without adding any material to dissolve metal at high temperature, without adding silver sheet, effectively reducing the production cost of glasses factory, achieving one-time investment and lifelong benefit.

04. Combined with computer technology, it is easy to realize automation, and the equipment operation is simple and easy to learn, and there is no need to hire a professional master with high salary.

05. Due to the advanced processing method, the existing product structure and materials can be improved, and the workpiece quality can be improved.

TECHNICAL PARAMETERS

| Product model | FT-Y-W200 | FT-YP-W500 |

| To large laser output power | 200W | 500W |

| Laser type | YAG | CW |

| Laser wavelength | 1064um | 1080um |

| pulse width | 0.1-4ms | 0.1-20ms |

| Single pulse to high energy | 80J | 200J |

| Pulse frequency | 0-120HZ | 0-5000HZ |

| Laser welding depth | 0.1-0.6mm | 0.1-2mm |

| Laser welding range | 200x200mm | 200x400mm |

| Flare adjustment range | 0.1-1.5mm | 0.1-2mm |

| Standard worktable to large bearing capacity | 25KG | 25KG |

| Repetition accuracy of working beam | -0.001mm | -0.001mm |

| Positioning accuracy of working beam | -0.001mm | -0.001mm |

| Aiming and positioning system | HD-CCD monitoring system | HD-CCD monitoring system |

| Cooling system | water-cooling | water-cooling |

| Rated input power of power supply | 5KW | 3KW |

| Overall power | 5KW | 3KW |

| Power demand | AC220V/380V+-15%/50HZ/25A | AC220V/380V+-15%/50HZ/25A |